The Igea implant system is the result of Mesa’s 50 years of experience in the dental industry and a constructive discussion gained over time with dentists. The research and development team based its knowledge on the latest state of the art and designed an implant with a simple and functional systematics. The two terms simple and functional well summarize the dual goal the company is committed to: to ensure innovative solutions that at the same time meet clinicians’ expectations.

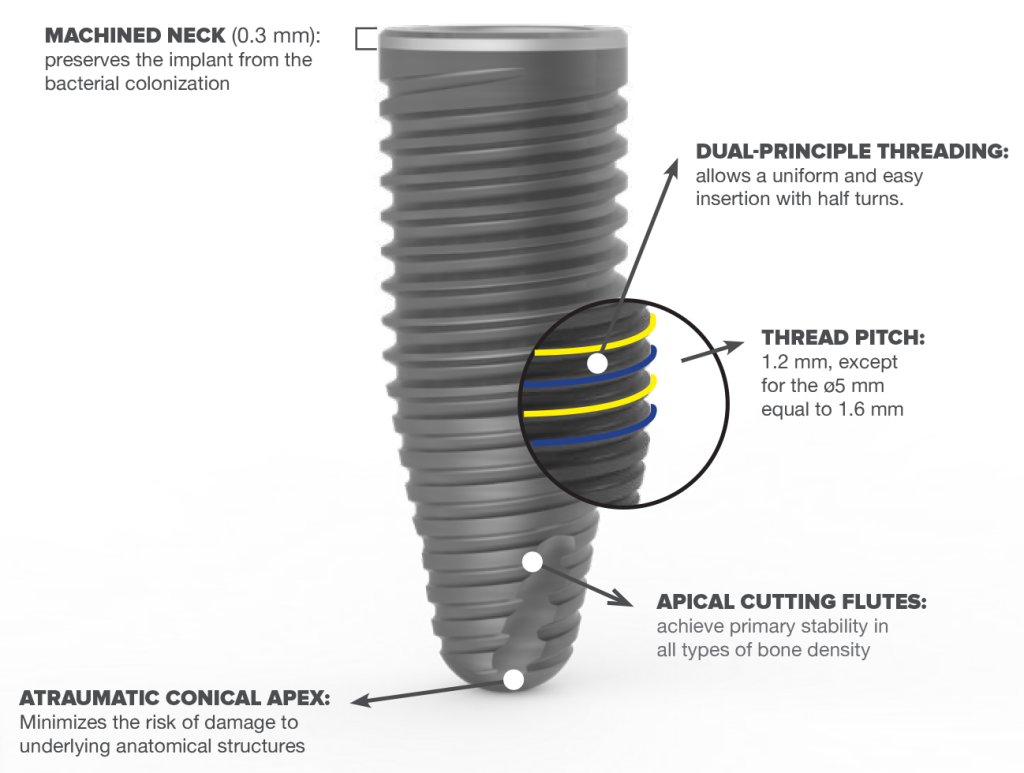

The conical-cylindrical shape of the implant guarantees a

optimal and uniform distribution of masticatory load. The 0.3-mm machined collar preserves the implant from bacterial colonization.

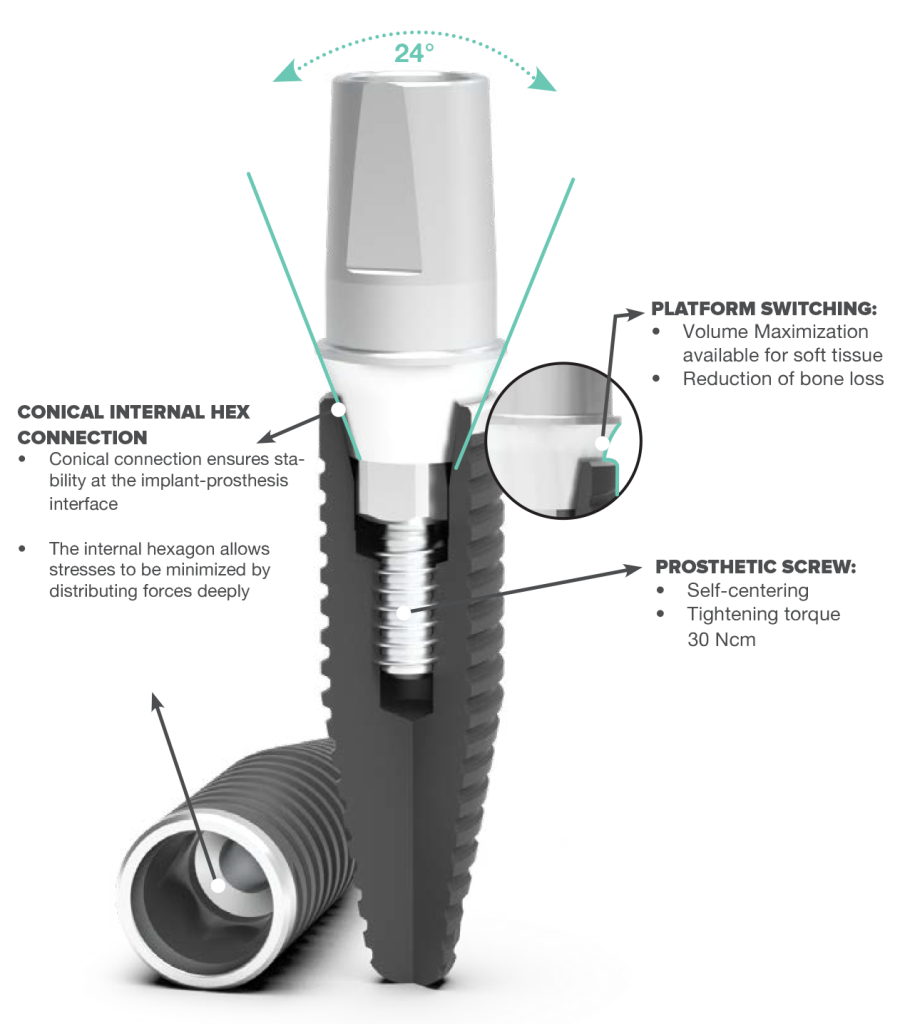

The conical connection with internal hexagon offers the possibility of balancing load forces acting on the prosthetic component preventing even potential unscrewing

phenomena.

Mesa Igea implants are available with Narrow and Regular platforms. The use of Igea Narrow implants in posterior areas is not recommended.

A versatile system with diameters and lengths adaptable to all major clinician needs.

The company uses Grade 4 Titanium to produce its entire line of dental implants. This alloy provides rapid osseointegration, excellent biocompatibility and has the highest mechanical strength among commercially pure Titanium grades.

Mesa Italia operates thorough cleaning processes on all facilities through advanced technologies to remove any traces of dirt from industrial processing.

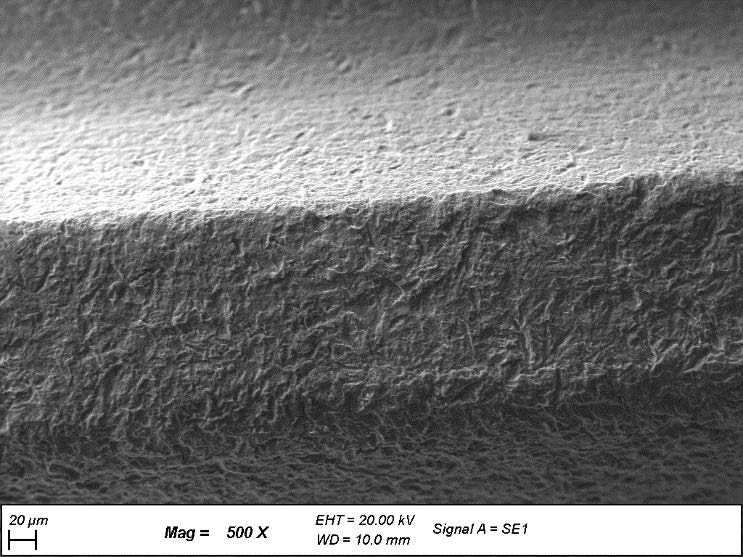

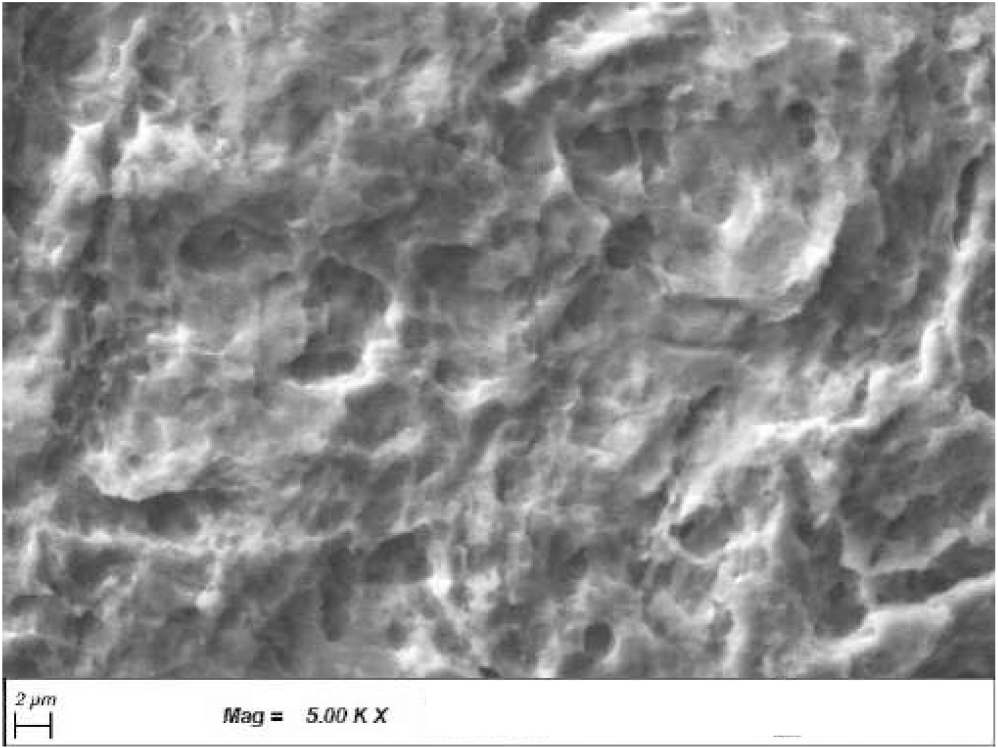

The surface treatment performed on Mesa Igea implants involves a process of sandblasting and subsequent acid etching in order to increase the contact surface area and promote osteoblastic cell differentiation.

Via dell’Artigianato, 37

25039 Travagliato, Brescia, Italy

+39 030 686 3251

info@mesaitalia.it

© MESA ITALIA S.R.L. | P.I. 00623390176

Ci impegniamo a rispettare la tua privacy. Lavoriamo ogni giorno per ridurre al minimo l’uso dei cookie, anche quelli tecnici, ma alcuni sono indispensabili per permetterci alcune attività. Puoi decidere tu come proseguire.